Expert Tips for Choosing Aftermarket Construction Parts

Wiki Article

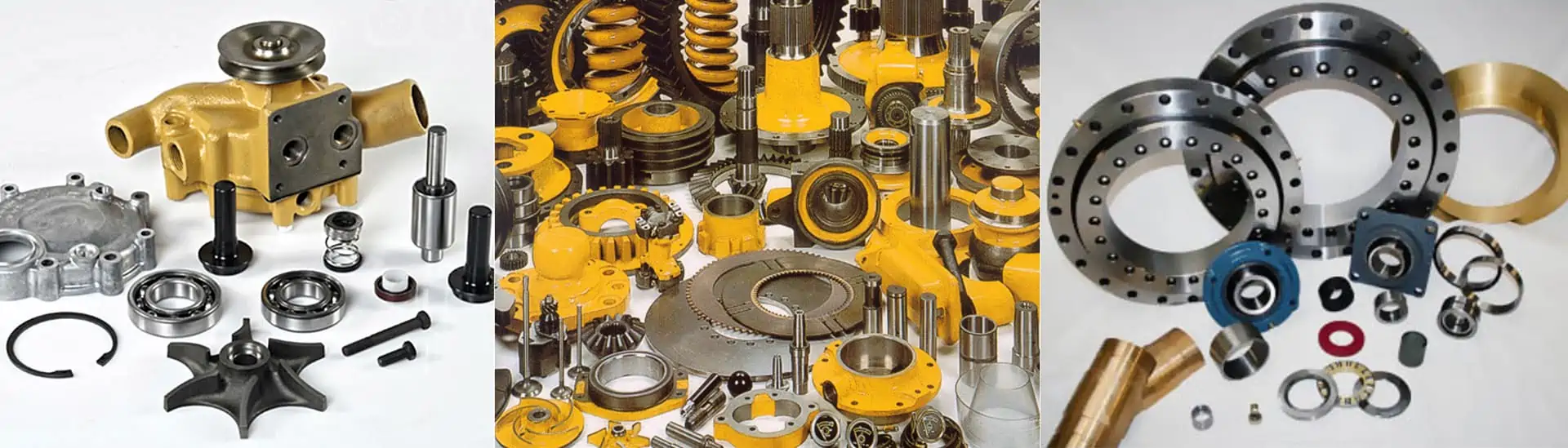

Boost Performance With Premium Aftermarket Construction Components for Heavy Machinery

Advantages of Premium Aftermarket Parts

When thinking about hefty machinery maintenance, deciding for costs aftermarket parts supplies substantial advantages in terms of cost-effectiveness and efficiency integrity. Premium aftermarket components are developed to satisfy or surpass the original tools manufacturer (OEM) requirements, ensuring a high degree of quality and compatibility. These parts are often more inexpensive than their OEM equivalents, making them a cost-effective option for organizations wanting to maintain their heavy machinery without jeopardizing on performance.Construction sites and industrial setups can be extreme settings, putting immense stress on machinery parts. By picking premium aftermarket components, businesses can lessen downtime, reduce maintenance expenses, and make certain that their machinery runs at peak performance.

Enhancing Equipment Efficiency

One of the substantial benefits of utilizing costs aftermarket components for heavy machinery maintenance is the improvement they bring to machinery efficiency in requiring functional atmospheres. Furthermore, costs aftermarket components can aid maximize fuel consumption, reduce downtime for repairs, and minimize the danger of unexpected breakdowns, eventually leading to a smoother and a lot more efficient operation of hefty machinery in numerous construction and industrial setups. Investing in premium aftermarket parts is a tactical choice for business looking to improve the efficiency and long life of their heavy machinery fleet.Economical Solutions for Upgrades

Applying cost-effective remedies for upgrades in heavy equipment maintenance can substantially affect operational performance and total performance. These aftermarket components undergo strenuous testing to ensure they satisfy industry standards and specifications, making them a trusted option for equipment upgrades.Normal maintenance and timely upgrades can help avoid costly downtime and extend the life expectancy of heavy equipment. An additional economical strategy is to invest in innovation upgrades, such as telematics systems, which can enhance equipment monitoring and efficiency optimization - aftermarket construction parts. These systems make it possible for real-time monitoring of device wellness metrics, enabling proactive upkeep and minimizing the risk of unanticipated failures

Boosting Machinery Longevity

Enhancing the resilience of hefty machinery is vital for optimizing operational effectiveness and decreasing overall maintenance expenses. Increasing equipment longevity involves implementing proactive measures to expand the lifespan of tools. Routine maintenance schedules, including oil adjustments, filter replacements, and assessments, are necessary to protect against premature wear and identify prospective concerns before they rise. Using top notch aftermarket parts particularly created for hefty machinery can likewise add to extending the life-span of tools. These components are frequently much more reputable and durable than conventional OEM parts, providing increased durability to severe working conditions. Furthermore, purchasing sophisticated innovations such as telematics systems can provide real-time information on maker efficiency, enabling drivers to attend to upkeep requirements immediately and effectively. By focusing on equipment longevity through a mix of preventative upkeep practices and quality aftermarket parts, building firms can improve the efficiency and Resources cost-effectiveness of their operations while lessening downtime because of unforeseen break downs.Optimizing Machinery Functionality

To guarantee the peak efficiency of hefty machinery, enhancing equipment performance is necessary for building companies intending to optimize functional performance and lessen downtime. One vital aspect of enhancing equipment functionality is performing normal maintenance checks to determine and deal with any type of prospective issues before they escalate. Implementing a preventative maintenance timetable can help in discovering worn-out parts or elements that may prevent the equipment's efficiency. Additionally, using innovative technology systems and software application for keeping an eye on tools health and wellness and efficiency metrics can give real-time information insights, making it possible for positive maintenance treatments.Including performance monitoring systems can help in evaluating machinery use patterns and determining areas for improvement or modification to enhance performance. By focusing on equipment capability optimization, construction firms can improve productivity, extend machinery life expectancy, and eventually attain greater returns on their hefty equipment financial investments.

Final Thought

When taking into consideration heavy machinery maintenance, deciding for premium aftermarket components provides substantial advantages in terms of cost-effectiveness and performance dependability.One of the substantial advantages of using costs aftermarket parts for hefty machinery upkeep is the improvement they bring to equipment performance in requiring operational environments.To ensure the peak efficiency of hefty machinery, optimizing equipment capability is essential for building companies aiming to take full advantage of functional efficiency and lessen downtime. By prioritizing machinery functionality optimization, construction business can boost efficiency, extend machinery lifespan, and eventually accomplish greater returns on their heavy machinery financial investments.

In verdict, utilizing costs aftermarket building and construction parts for hefty machinery our website uses various benefits, including enhanced efficiency, cost-effective upgrades, enhanced durability, and optimized functionality.

Report this wiki page